A Overview of My Skills

This is a brief overview of the skills I bring to the table! Scroll down for a more in-depth view into my capabilities and talents!

3D Modeling Software

I have extensive experience in a variety of modeling software including:

- Solidworks

- Siemens NX

- Autodesk Inventor

- Fusion 360

Rapid Prototyping

I've learned how to use FDM and SLA printers in order to rapidly produce prototypes of designs I've been working on. I use my 3D modeling skills to produce print-ready parts for testing and applications!

Machining & Manufacturing

I'm skilled in a variety of machining and standard manufacturing tools including CNC and manual lathes, vertical and horizontal mills, 5 axis CNC mills, and laser cutting or engraving.

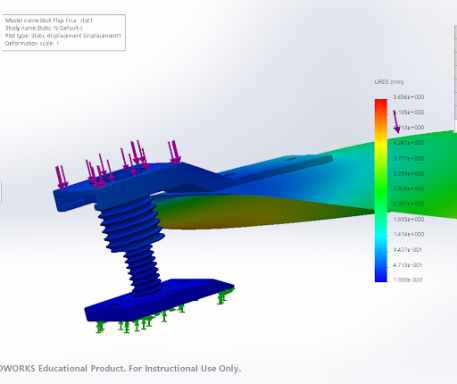

Simulation

Utilized Solidworks Simulation to perform Finite Element Analysis to test mechanical failures and update models accordingly. Used ANSYS Fluid to simulate blood flow in veins and airflow in designed parts.

Coding

Learned MATLAB for modeling complex ODEs in regard to biomedical systems. Further developed on the knowledge in a Mechatronics class learning about and modelling different controllers. Also learning C# and hoping to start in Python

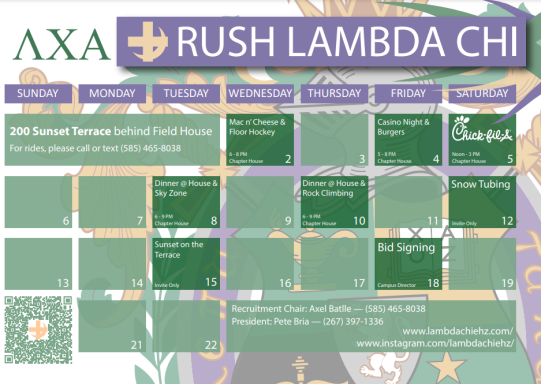

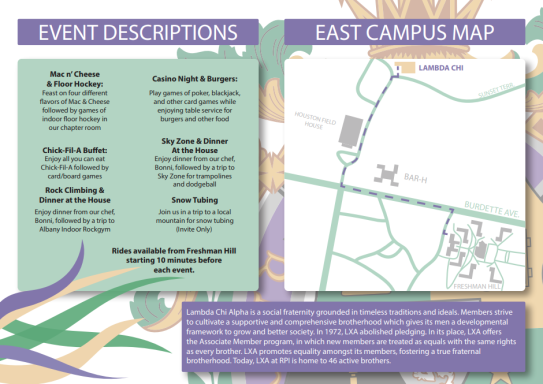

Design Tools

Learned the Adobe Suite, namely Photoshop and Illustrator for interest in Graphic Design. Have since used an iPad and Procreate to begin designing tattoos as well as other artwork. I have designed posters and flyers for my fraternity, tattoos for myself, and other works

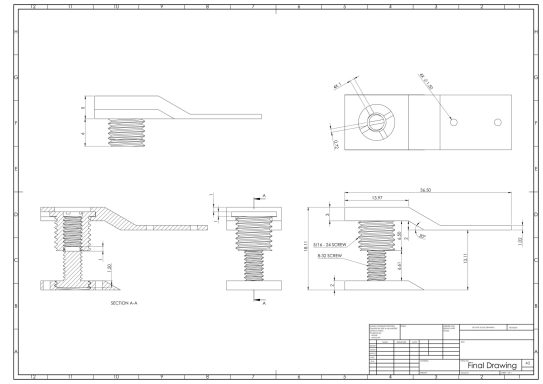

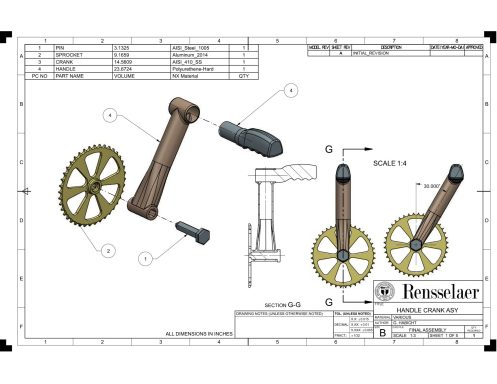

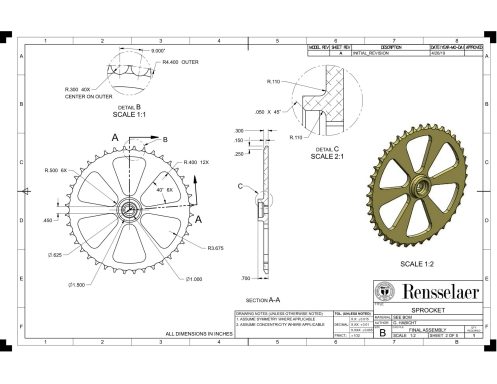

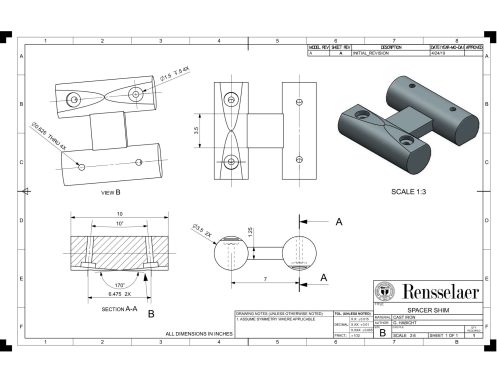

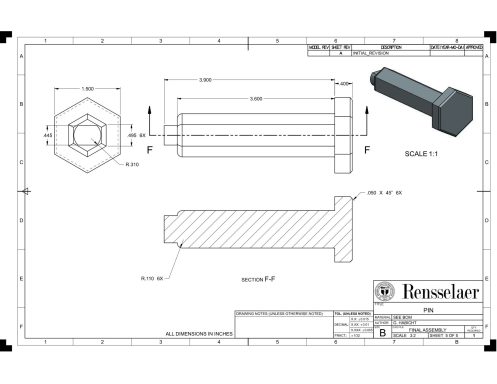

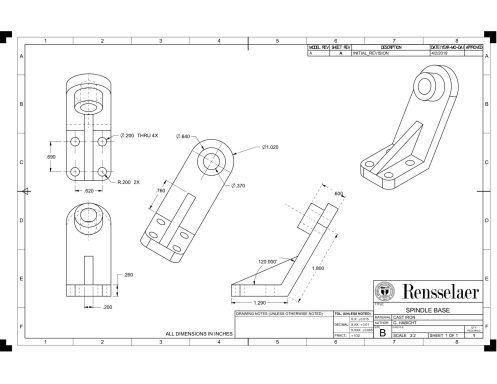

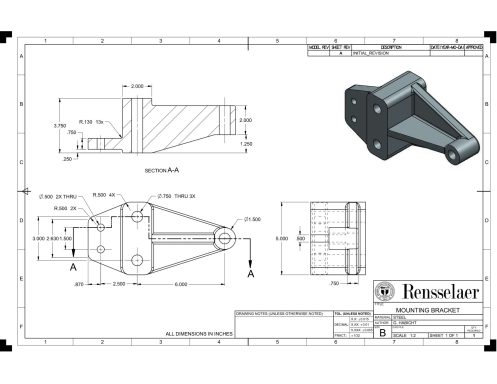

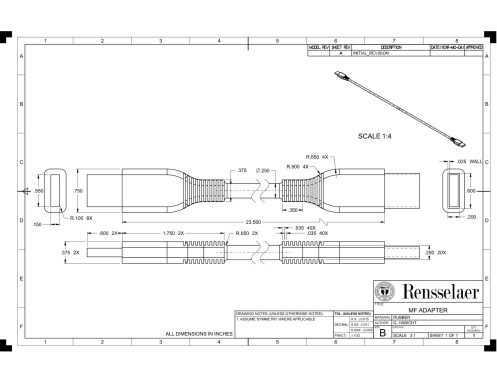

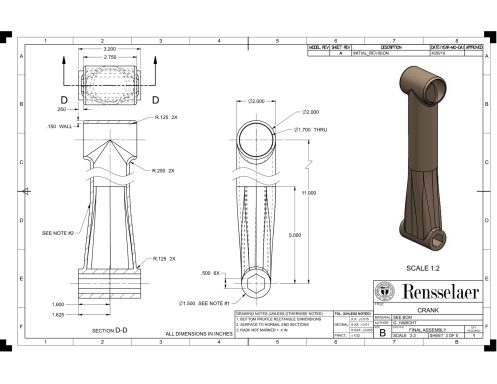

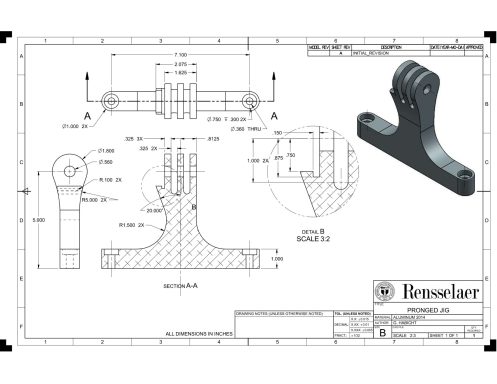

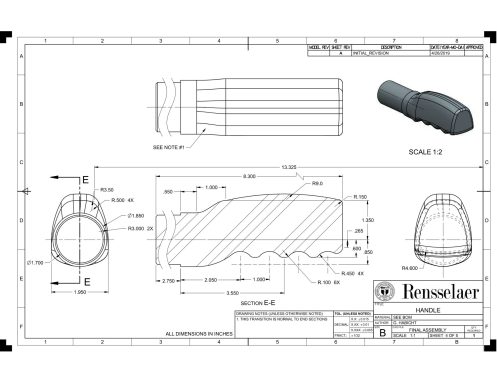

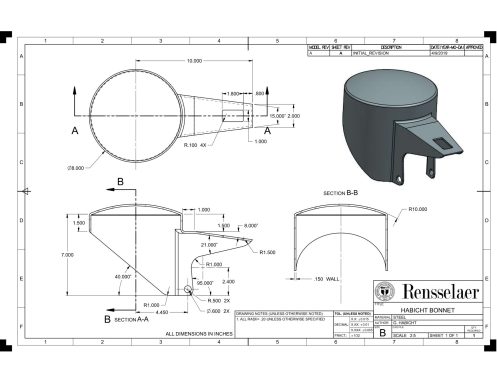

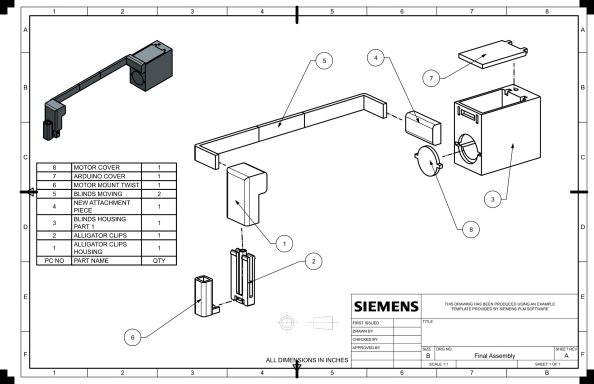

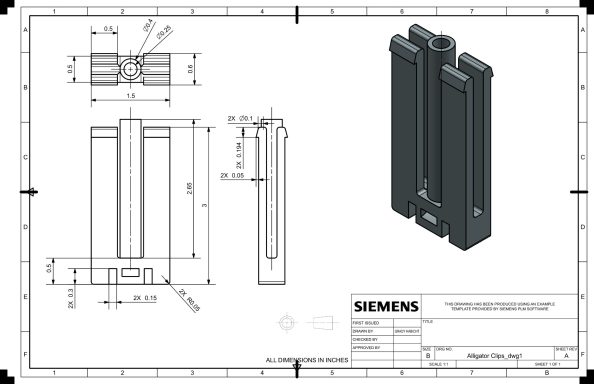

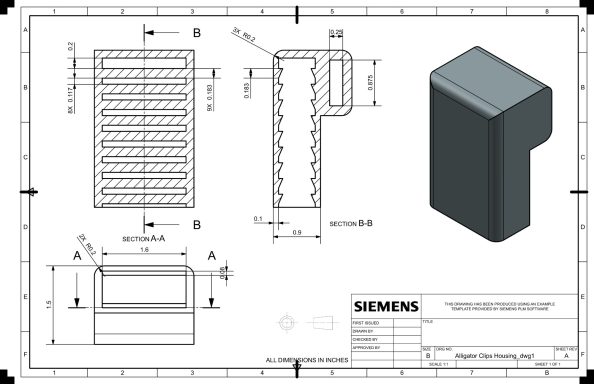

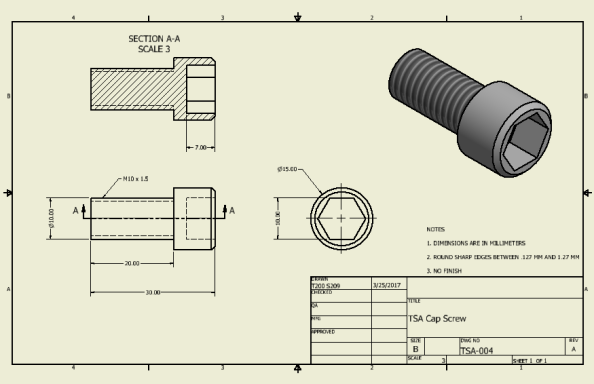

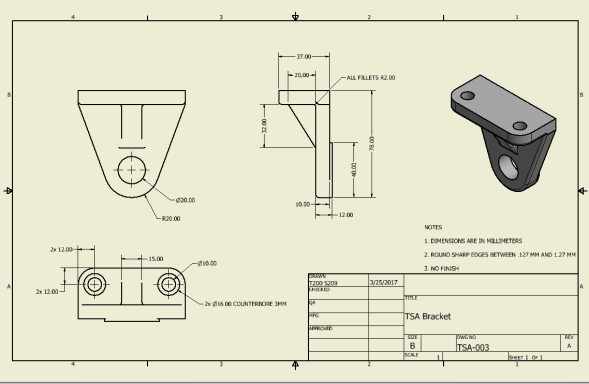

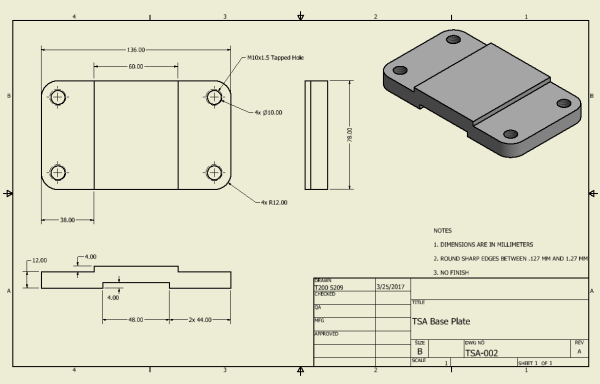

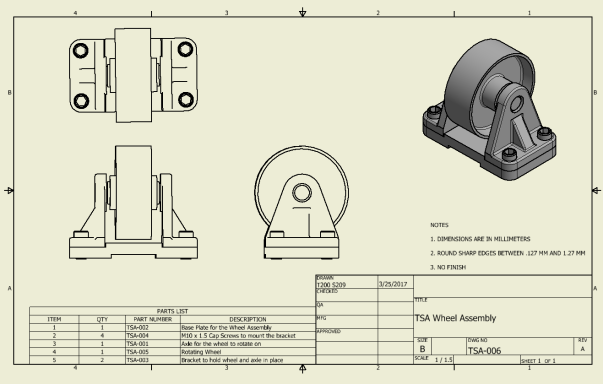

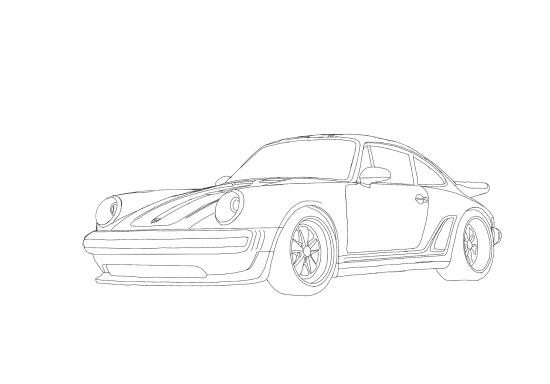

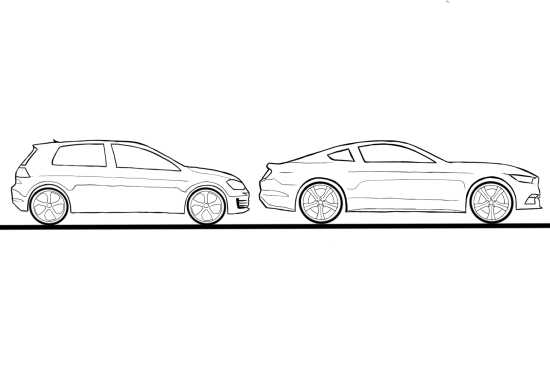

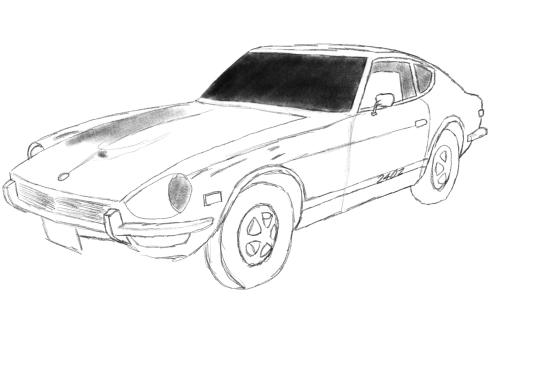

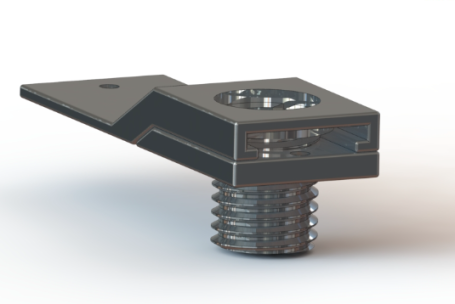

3D Modeling Software

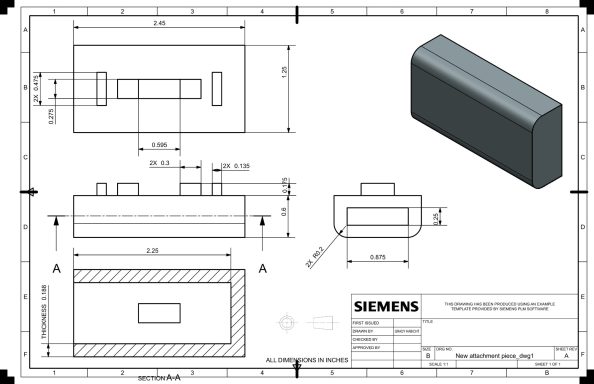

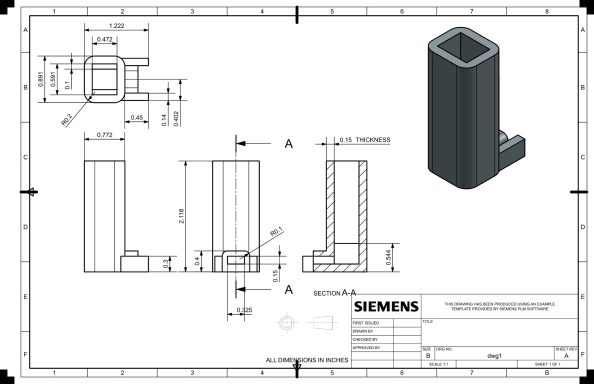

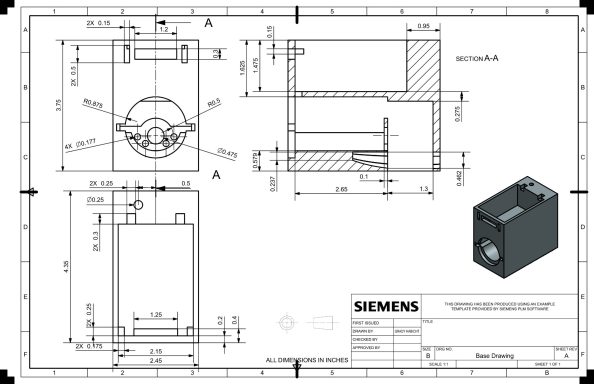

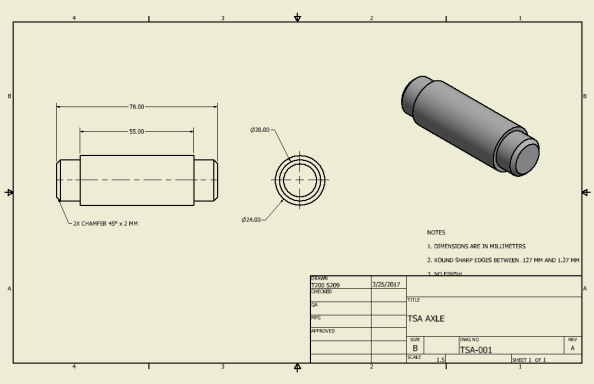

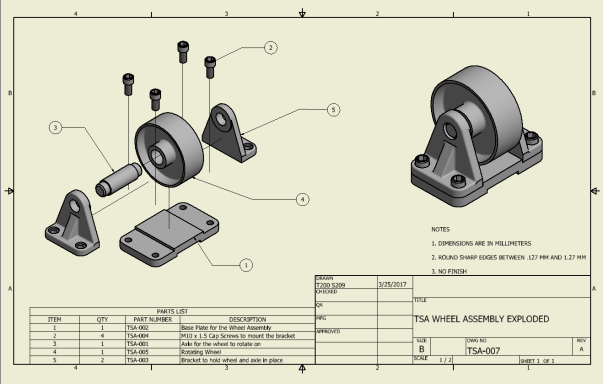

I've used a variety of 3D Modeling programs throughout my time; Here are some example drawings of parts I've made for competitions, classes, or personal hobbies!

These drawings were made in Solidworks, Siemens NX, and Autodesk Inventor.

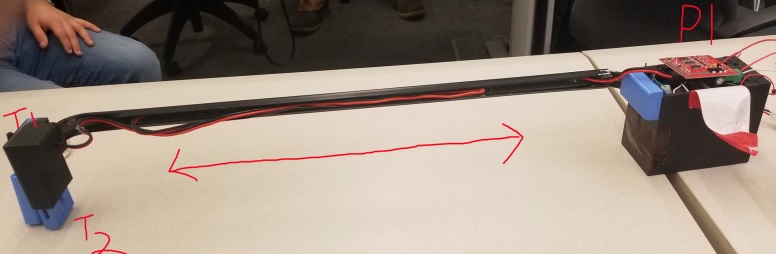

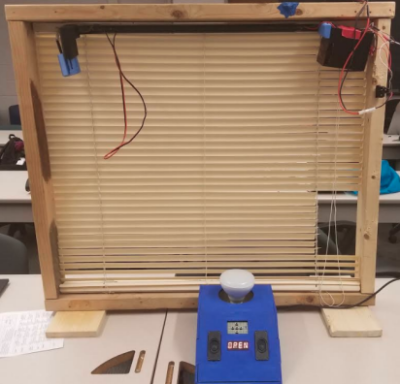

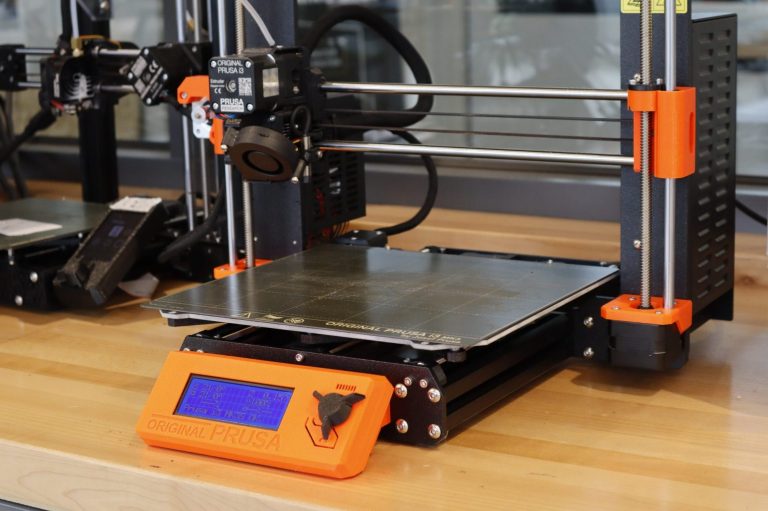

Rapid Prototyping

Mostly using Prusa MK3S to rapidly manufacture models of project designs.

Combining knowledge of standard manufacturing and assembly processes with additive manufacturing in order to produce effective prototypes quickly to demonstrate functionality, fit, or other important testing pieces.

Machining & Manufacturing

Starting in the 7th grade, I joined an alternative energy race team where I learned how to weld, wire, machine parts, etc while making cars that ran off of two 12v car batteries. I also learned how to solder here. This started my passion for cars and tinkering!

In college, I took a class called "Engineering Processes" where we learn how to manufacture a variety of parts using a vertical mill, horizontal mill, CNC lathe, manual lathe, a laser cutter, and more. This knowledge has been crucial to me in designing parts, as I know what is a feasible design.

I utilize these skills to help in my personal projects, as well as just general know how in assembly and manufacturing which helps with troubleshooting in my current job!

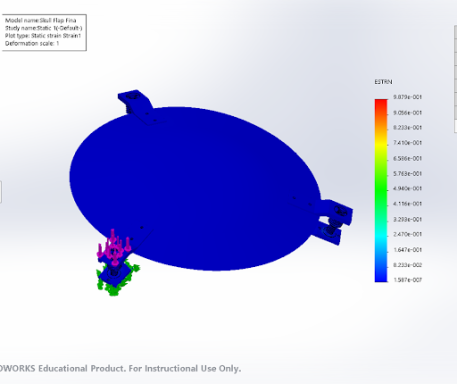

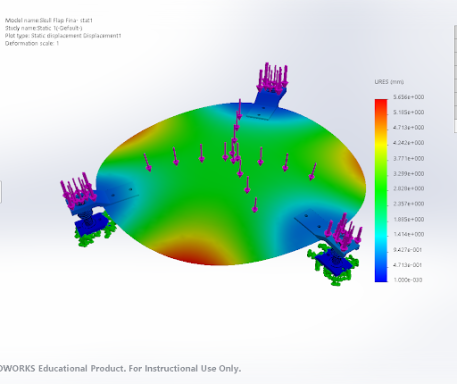

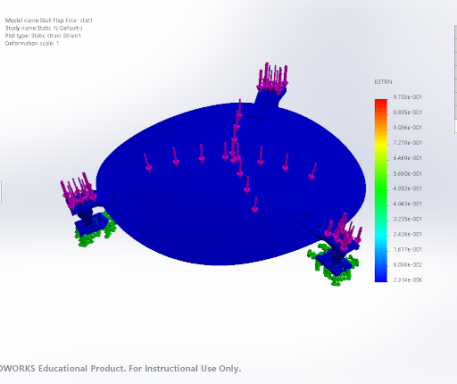

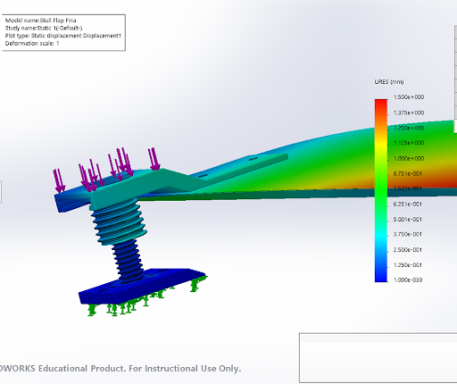

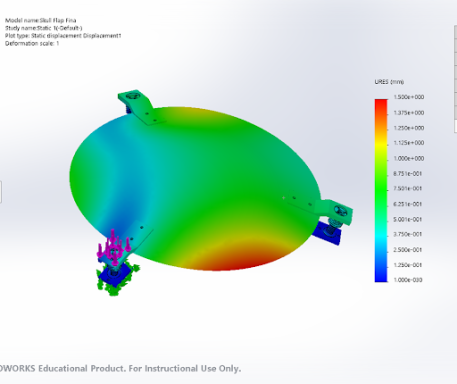

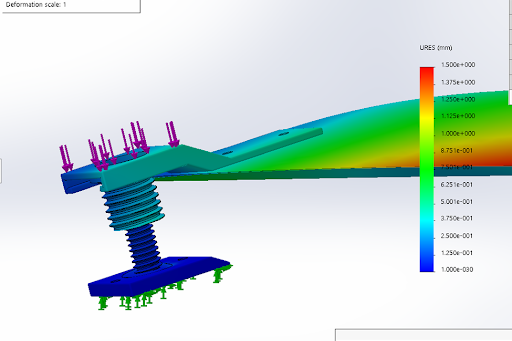

Simulation

Here are some examples of FEA performed in Solidworks for my Capstone project to verify the design's rigidity and functionality regarding the skull flap and mounting points. We wanted to make sure the combination of the device and bone could withhold the standard forces we would expect someone undergoing an ICP to expect. Titanium was used for the device and we found a comparable bone material to use for the skull flap.

Coding Skills

Throughout college and in personal hobbies I have learned how to code at a very basic level in a variety of programming languages.

The program I have the most experience in though is MATLAB, which I used to model complex ODEs for a Biomedical Systems class, as well as used it in a mechatronics class to design a PID controller which was ultimately used to balance a LEGO robotics toy.

I'm beginning to learn C# for my work, and will soon take the venture out to python!

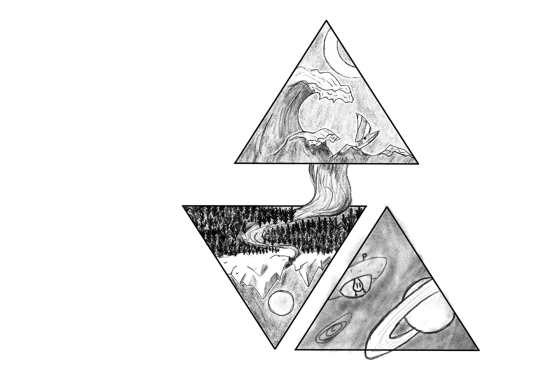

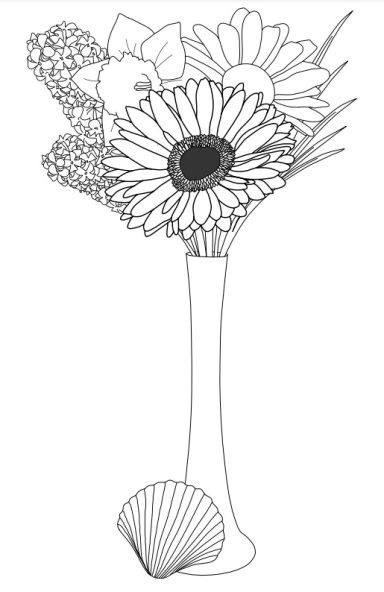

Design Tools

A brief collection of my works. All are made in either Photoshop, Adobe Illustrator, or Procreate!

©Copyright. All rights reserved.